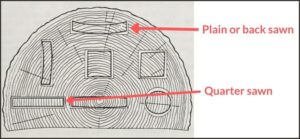

Depending on how your timber is cut, it will shrink in different ways as it dries out. Most timber cut by pine sawmills today is “plain sawn” or “back sawn”, and will have a high amount of tangential shrinkage. This means the timber will tend to cup as it dries.

“Quarter sawn” typically has the least amount of cupping due to the parallel growth rings right across the board. This will result in some radial shrinkage, but a much more stable piece of timber overall. A lot of the hardwood mills quarter saw to improve the stability of the finished product.

There are two easy ways to help reduce cupping and shrinkage that you should advise customers. The first is the correct fasteners or fastening systems, as these will help fasten your timber securely and go a long way towards minimisation of cupping. And using a highquality penetrating timber oil will help equalise the moisture in the timber, slow down the drying, and prevent excessive take up of water in rain conditions. Timber oil should also be re-appliedas required, or when the water stops beading